|

| |

|

Examples of spare parts and

components being produced, repaired or design modified by

SEBEMATEC:-

|

All

these parts including the main shaft and couplings of special

steel are either produced by SEBEMATEC in stainless steel 316

qualities or fully reconditioned and high-speed dynamically

balanced according to the corresponding grade of ISO 1940.

Original pump rotor after reconditioning by SEBEMATEC NiCr- protection sleeves of pump shafts Rotor with adjustable blades being reproduced

by SEBEMATEC

Original pump rotor after reconditioning by SEBEMATEC

|

SEBEMATEC offers a comprehensive programme for pumps’ parts

reproduction or reconditioning, such as pump housings, wear

rings, impellers, labyrinths, ceramic and rubber coating

resisting to aggressive chemicals, wet abrasion and

cavitations. Petrochemical, irrigation, power plants, water

stations, foodstuff and chemical industries are our major

customers in this field.

SEBEMATEC produces pump casings to suit actual operating

conditions either of cast iron GG 20 or 25 or of stainless

steel 304 or 316. The company is capable to cast wear rings

of NI-hard/white cast iron or of copper alloys resisting to

sea water. The delivery programme includes the associated

driving transmission system and all kinds of couplings of

pumps

Anti cavitations’ coating Overhaul of cast iron sewage pumps

Anti cavitations’ coating

|

Reproduction and/or rehabilitation of boilers’ feed-water

pumps for electricity generation plants. Professional

overlaying of impellers, shafts, labyrinths and wear rings.

Certified high-speed dynamic balancing acc. to ISO 1940

grade G: 2,5.

Set of stages of 12 % Cr after being overhauled. Production of wear rings of martensitic hardened steel. Stages and rings quality upon delivery.

Set of stages of 12 % Cr after being overhauled.

|

SEBEMATEC produces or rehabilitates individual parts for the

entire range of valves used in the industrial fields.

Interior coating resisting to wear and chemicals is carried

out by special top-quality ceramic and rubber coating

against corrosion, erosion and cavitations.

Condenser seawater butterfly valves Complete programme for valves’ overhaul and testing

Condenser seawater butterfly valves

|

SEBEMATEC produces all kinds of steel rolls without

surface coating or coated with special ceramic and

elastomeric coating resisting to the most aggressive

chemicals, abrasion, erosion and heat. The company is

very specialised in repair of non-metallic perforated

dewatering rolls for paper industry.

|

SEBEMATEC produces an extensive wide range of parts and

components for crushers and mills for mining and

quarries, e.g. jaw -, cone -, hammer crushers and mills.

We offer parts, such as eccentric shafts, bearing

carriers, gears, fly wheels, crusher housings, distance

pieces, conveyor elements and interior cladding by

hardened wear-resisting plates.

Heavy Duty Eccentric Shafts for Crushers

|

SEBEMATEC offers an exclusive production programme

for paper industry covering replacement or

rehabilitation of parts such as cyclone separators,

waste traps, pulpers, high-pressure water spray

systems, coating equipment, paper mill driving

gears, transmission systems, screw conveyors,

steam-drying rolls, complete range of rolls being

steel, rubber or ceramic coated or perforated as

dewatering

rolls. Abrasion resisting or hardenable martensitic

rotors are also produced by us. We recondition the

entire range of stock pumps and process valves.

Repaired waste paper pulper Vacuum Copper Dewatering Roll

High-pressure water spray system

Repaired waste paper pulper

|

SEBEMATEC

produces a wide range of components and spares for heat

resisting applications up to 1150

°C.

Burner

components, burner carriers and hot air deflectors are some of

the major components being produced in this field.

Repair of Turbine Crossfire Tubes

|

SEBEMATEC produces special parts according to

customer drawings or samples, such as gear

couplings, gears, special screws,

transmission elements, sprockets,

compressor components and bushings of

copper alloys for industrial heavy loads’

application. Ward cups, marine propellers and

shafts are also produced to customer

requirement.

|

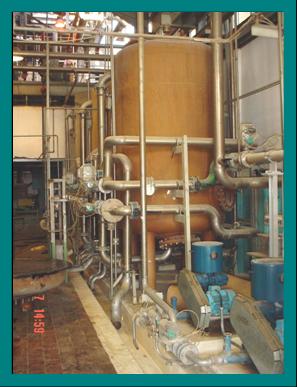

SEBEMATEC builds tanks acc. to customer design and drawings with

special corrosion protection coatings that are developed to

protect metal surfaces operating in any industrial environment.

The tanks are coated by the latest polymer technology and

provide an excellent degree of protection against aggressive

chemical attacks. SEBEMATEC is capable to recommend to customers

the durable rubber, ceramic or epoxy coating depending on the

kind of chemicals, concentration, temperature etc

Cationic filters’ rehabilitation and design modification in one

of the Egyptian paper mills in the boiler water treatment plant.

Left and right photos show the filter screens after being

rehabilitated. Filter interior has been coated by chemical

resisting rubber, fully sealed and self-cured by hot air and

then exposed to the standard process vacuum.

|

SEBEMATEC produces special parts according

to customer drawings, samples or

re-engineers parts’ design to meet the

actual running conditions at site to

increase service life-time of component in

question.

A wide range of special steel grades

including case-hardened steel, full-core

hardened steel, cold or hot working steel,

heat and abrasion resisting steel is

available in stock. A complete range of

rubber and ceramic coating qualities are

available to increase life-time of parts in

aggressive chemical and abrasion media.

|

SEBEMATEC is equipped to handle miscellaneous industrial

requirements (jobbing) according to different customers

demands disregarding whether it is a big or small

quantity. The factory offers precision sheet-metal works

of high-alloyed steel, heat exchanger tube plates and

tube elements, special components for cement industry,

brick and ceramic industry and a complete range of

components for water treatment plants, such as aerators,

screw conveyors, agitators and intake-screens etc.

Heavy duty component repair or reproduction for cement industry

Upgrading of handling systems for different industries Turn-key service for different sections of water treatment plants.

Heavy duty component repair or reproduction for cement industry

|

SEBEMATEC experts were the first to

apply in the Egyptian market a

comprehensive repair of turbine rotors

and high-speed rotating shafts

overlaying by low-heat professional

welding technique keeping the standard

run-out limit tolerance of the shaft in

question. Remachining and cylindrical

grinding of the shaft as well as soft

bearing dynamic balancing is carried out

according to ISO 1940 valid criteria.

SEBEMATEC carries out complete rotor overhaul and then applies

soft-bearing high-speed dynamic balancing according to the

corresponding standard. In the above shown cases, considering

the actual running speed of 5500 RPM, the standard ISO 1940

grade G 2,5 is applied. The company is ready to export high

quality dynamically balanced products supported by

balancing certificates. This includes - but not limited

to - pump rotors, couplings, industrial fans, rotary screens,

agitators, impellers and rotary hammers. A complete programme

for electric bobbins, shaft repair and rebalancing is available.

The company offers superior chemical resistance coatings for

industrial fans and chemical mixers.

|

SEBEMATEC produces a complete range of parts and

components for water intake screens for electricity

generation plants, irrigation and water treatment

stations. Driving chains of stainless steel and its

elements such as rolls, pins, etc. are produced with

the standard hardness and corrosion resistance

quality.

Mesh-screens and frames, scrapers, driving

sprockets, main driving shafts and transmission

systems are tailor-made to customer requirement.

Screen ready ex our works

|

|